What Happened?

In 2010, EPA promulgated the Lead-Safe Renovation, Repair, and Painting (RRP) Rule to protect people from lead-based paint hazards in homes and child-occupied facilities built before 1978. The rule requires the use of common sense work practices to reduce the generation of dust and debris, control the spread of those materials if generated, and require the cleaning and inspection of the work area when the paint disturbance is finished. EPA requires these work practices unless testing demonstrates the lead levels in all layers of paint are not high enough to be considered lead-based paint.1

The RRP rule prohibits the most dangerous work practices: 1) open-flame burning or torching of the paint; 2) use of heat gun at temperatures above 1,110oF; and 3) use of high-speed sanding machines to remove paint unless a special shroud and filter ensures no visible dust escapes. The ban on dry machine-sanding without a shroud/filter is particularly important because contractors find it easy and fast to use, despite the danger to themselves, their families, their customers, and their customer’s neighbors.

This rule came into acute focus recently for Unleaded Kids National Director Tom Neltner. His neighbor hired an EPA-certified RRP contractor to paint their home. Both Neltner’s and the neighbor’s split-level homes were built in 1957. Neltner confirmed that his house has lead paint when he tested his outdoor paint a decade ago with LeadCheck Swabs prior to repainting the house himself. Therefore, his neighbor’s house probably contains lead paint as well.

Hours after the contractor began work on his neighbor’s home, Neltner saw the contractor machine-sanding a third-story face of the roof gable. The contractor’s head was in a cloud of dust. Neltner’s fruit and vegetable garden was close enough to be contaminated. The contractor had already sanded the paint on other areas of the home.

Neltner called his neighbor, who immediately told the contractor to stop the work and shared with Neltner the contractor’s EPA-issued RRP certificate. It had been issued in January 2024, meaning the contractor completed the required training only a few months earlier.

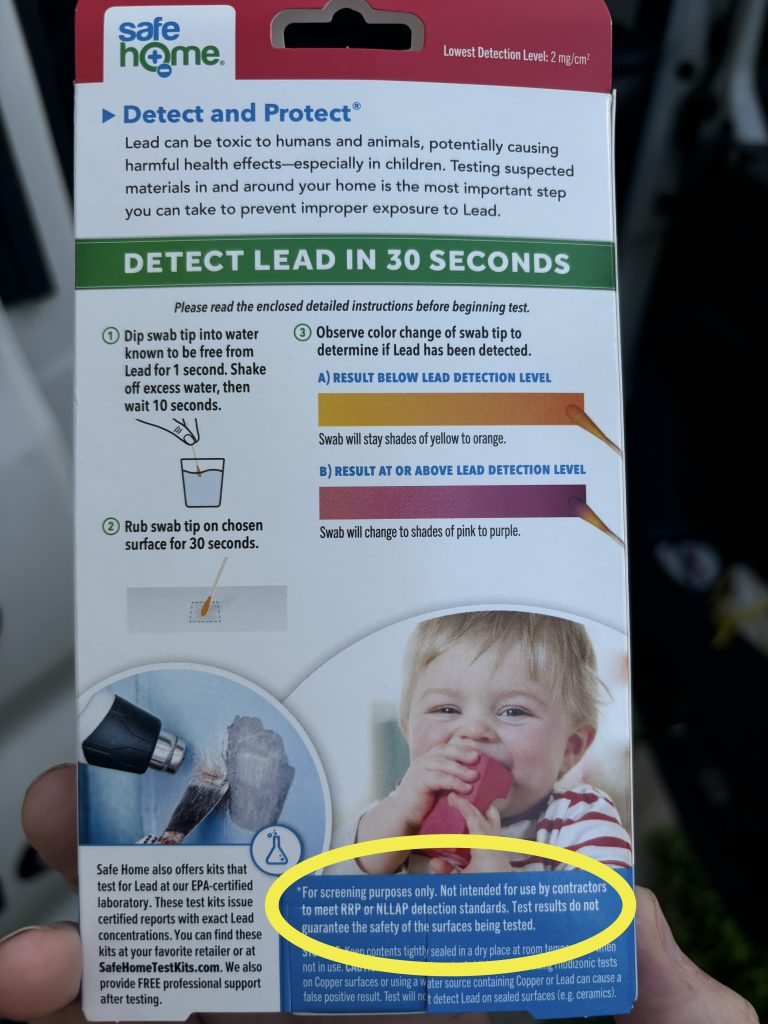

Later that day, Neltner talked with the contractor who explained that he had not tested the paint because he was only disturbing the surface layer. Neltner explained the risks and raised concerns about his fruits and vegetables from the garden being contaminated as well as the risk of serious lead poisoning for the contractor and his family. The contractor said that after the neighbor stopped his work, he went out to find LeadCheck Swabs.2 Instead, he could only find the SafeHome Do-It-Yourself Lead Test Kits (Figure 2). On the back of that box, it says in fine print that the kits are not intended to be used by contractors to meet RRP standards (Figure 3).3 The contractor maintained that the swabs show the paint was not lead-based because he rubbed it on the intact surface of the paint, missing the original paint.

With the neighbor’s permission, Neltner filed a complaint on June 17 through EPA’s website. The EPA has not yet responded.

Why it Matters

The goal of lead-safe work practices is to avoid generating lead debris or dust, because, once generated, it can spread far and is difficult to fully clean-up. EPA has banned certain dangerous work practices because their use is virtually guaranteed to make fine lead dust, even outdoors, that is easily carried by even a light wind.

Lead dust and debris from exterior renovations—even using lead-safe work practices—can spread into the home through open windows and doors and contaminate nearby gardens, patio tables, grills, and soil. For that reason, EPA’s RRP rule requires contractors to cover the ground with plastic sheeting 10 feet from the disturbance to capture dust and debris. Vertical containment is required if the work is within 10 feet of the property line. Those protections are grossly inadequate when someone uses prohibited work practices such as dry machine-sanding without shroud/filter.

Our Take

After 14 years, EPA’s lead-safe work practices should be the norm, whether by a contractor or a do-it-yourselfer. Unfortunately, they are not.

Even if the paint were not lead-based, it can contain significant amounts of lead—enough that EPA agreed in 2009 to re-evaluate the current limits. And when it did not complete the review, the Ninth Circuit Court of Appeals ordered the agency to do it.

Even if there were no lead in the paint, few people want a renovation or painting project to spread dust and debris from old plaster, drywall, or paint in or around their home.

While Neltner has no kids living in his home, the lead exposure from the contractor’s dangerous work practices puts the Neltners, their neighbors, and the contractor at greater risk of premature death from cardiovascular disease. In addition, if the contractor has maintained the same practices with other customers, the contractor has likely contaminated other homes and neighborhoods.

More broadly, the incident raises other questions:

- How could a renovator taking EPA’s mandated training miss that he must assume lead-based paint is present (unless he has tested using a valid test) and must not use the prohibited work practices? EPA needs to look closely at the training provider and determine what went wrong.

- Why has Maryland, where Neltner lives and which touts being a lead on lead-poisoning prevention, not adopted the RRP and ensured compliance to protect residents? While EPA is close to Maryland, it is not staffed to cover the many states that, like Maryland, either don’t consider the risk sufficient to protect their residents or somehow think that EPA can do a better job.

- How many people don’t have excellent neighbors like Neltner who check for an EPA certificate and stop work when problems are raised? We cannot expect people to know what lead-safe work practices are.

- Why has 3M suspended the production and sale of LeadCheck Swabs, a valuable tool for homeowners and contractors? Could it be an indication of how little compliance there is with the RRP?

Next Steps

Unleaded Kids awaits EPA’s response and enforcement as it follows-up on a complaint.

- Those levels are currently 5000 parts per million (ppm) or 1 milligram per square centimeter (mg/cm2). ↩︎

- Apparently, 3M, the manufacturer of LeadCheck Swabs, has suspended production and sale. ↩︎

- Inexplicably, the Safe Home kit shows someone using a heat gun to dry scrape the paint. ↩︎